Welcome to your world's first

optical real time localization system

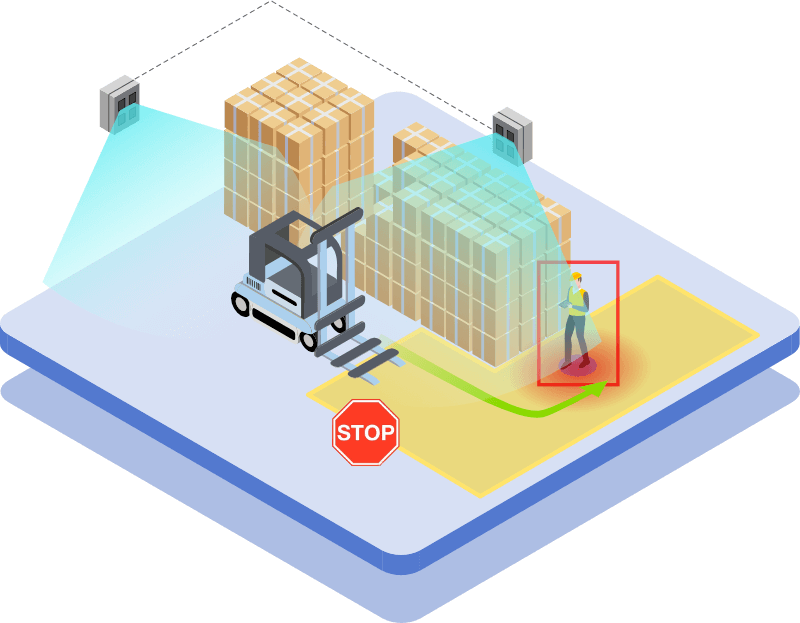

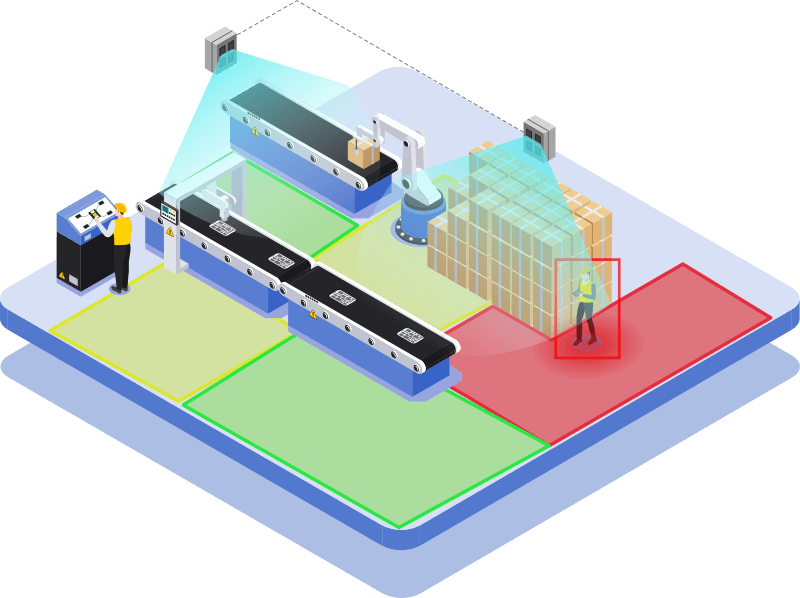

Collision prevention

If you use industrial trucks in your business and want to protect your employees and machines, our solution is the best choice for you.

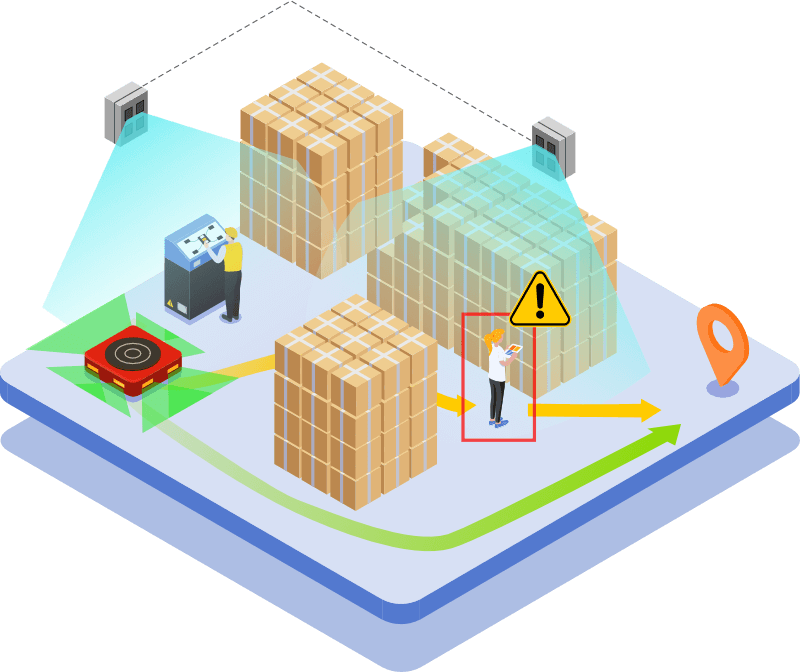

AGV Navigation

Despite a high level of automation and the usage of AGVs, undesirable situations often occur. We can prevent these through a holistic perspective.

Work analytics

Optimisation potentials are hidden in many areas. Even in areas you didn't expect. We uncover them for you - all in compliance with data protection law.

Why choose us

Digitalise your working environment

Many companies are following the trend of digitalisation. Why don't you? Browse our website and find out what our system can do and how you can use it to increase safety and efficiency for your employees and your machines!

How does it work

As easy as possible.

Everything in one place.

Through smart mounting and communication between the sensors, we create an intelligent network. Therefore, install the system just once and benefit from increased security and effectiveness of your working environment for years to come.

Stay updated and receive the latest news and articles!

Cutting the edge

See us in action

Watch our short video explaining everything you need to know. A typical scene in a warehouse or production. A forklift truck drives in a shallow aisle with its delivery to the drop-off point. And suddenly an employee comes around the corner who was not visible to the forklift driver before.

What do I need?

Get in touch with us!

As our system is versatile, we are looking forward to your enquiry and your challenges!