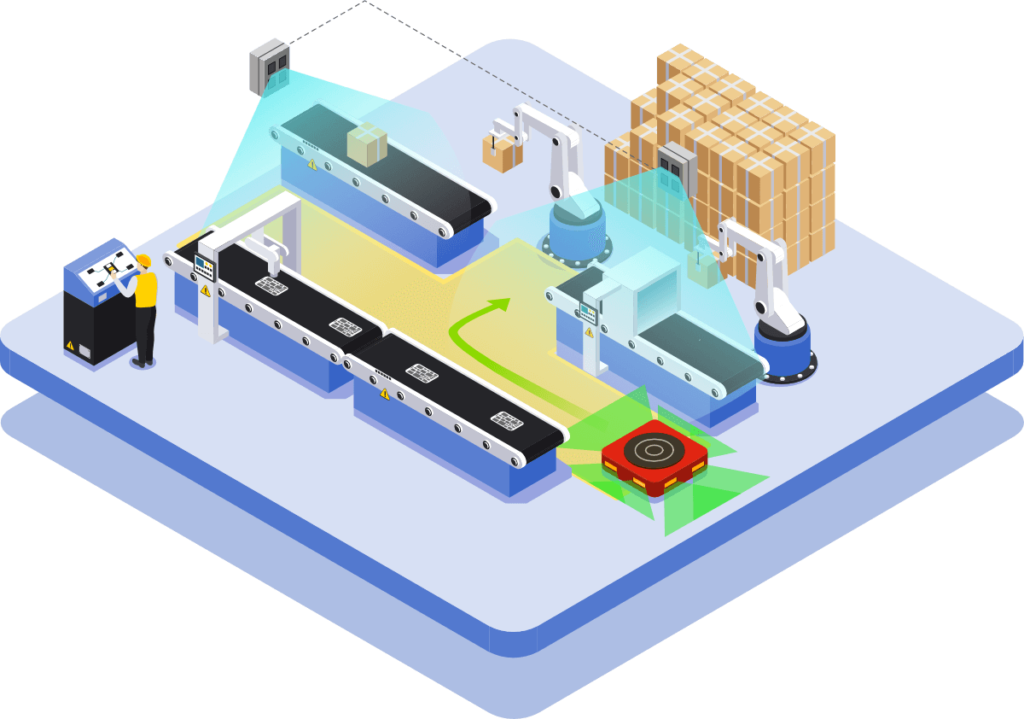

AGV Navigation

Narrow and difficult to survey corridors.

Due to the limited visibility of the onboard sensors, your robot may have to slow down or even stop. With holistic vision, the AGV knows exactly where it is and the likelihood of a collision. It can even increase its speed and reach its destination faster.

- Narrow corridors

- Short range of onboard sensors

- Frequent stops or getting stuck

- No structural restrictions

- Large area coverage

- Faster delivery

X-ray your environment.

Since our sensors are placed like a network in your working environment and therefore cover all blind spots, supposedly critical situations like collisions can be prevented.

We achieve this by dynamically computing walking and dring paths, which reduces the risk of a surprise encounter at an intersection that is difficult to overlook. This means that nothing stands in the way of close human-machine cooperation.

Smart decisions. Smart factory.

Despite a high level of automation, unexpected events can always occur. In particular, blocked paths or other failures can delay the whole process. But not only that. Keep an eye on your fleet, your machines and your material flow and use them wisely. It is therefore important to react quickly and efficiently to these changes in the environment. This is the only way to realise its full potential.

- Unpredictable situations

- Production must not stop

- No knowledge about exact workload

- Smart fleets

- Dynamic route adjustments

- Increased overview and efficiency

Get in touch with us!

As our system is versatile, we are looking forward to your enquiry and your challenges!